|

Home >> synthetic diamonds >> wire drawing dies |

Wire drawing is a metal-working process relies on a combination of a die and/or a series of dies to pull or draw a wire to a chosen gauge and is utilized to reduce the cross section of a wire. This process has in essence modified a very little through the years. Wire drawing dies are the tools with highly polished, specifically shaped holes by which a wire is drawn to decrease its diameter. They consist of a metal case and a nib made from monocrystalline diamond or polycrystalline diamond (PCD) or CVD diamond, PCD with carbide ring and each has its own field of applications. |

Mono Crystalline Diamond Wire Drawing Die

Synthetic single crystal diamonds, also known as synthetic mono crystalline diamond, abbreviated as SMCD or SSCD or MCD, are man-made diamonds, created under controlled circumstances and are totally free of pollutants, blemishes and crevices. These firmly controlled high quality elements lead to estimated and continuous die efficiency. A benefit of monocrystalline diamond wire drawing dies is always that the blank dimension is more reliable than natural diamond blanks, and thus provides a more foreseeable recut overall performance than natural diamond drawing dies. |

|

Applications

Mono crystalline diamond wire drawing dies are effectively applied in both ferrous and non-ferrous wire drawing industrial sectors, bonding wire in gold, aluminum, copper, medical wires, stainless steel, EDM wires, exclusive alloy and powerful alloy, precious metal wire types. |

| Monocrystalline diamond wire drawing die common sizes |

|

| MD-06 |

MD-07 |

MD-08 |

MD-09 |

| MD-10 |

MD-11 |

MD-12 |

MD-13 |

| MD-14 |

MD-15 |

MD-16 |

MD-17 |

| MD-18 |

MD-19 |

MD-20 |

|

|

| |

CVD diamond wire drawing die

The CVD diamond wire drawing die blank is likely to bring completely new vitality for the wire drawing die industry in the foreseeable future. It has high temperature and wears resistance which is much like those of higher level mono-crystalline diamond, much better than PCD material and has a cheaper price. There isn't any directional damage during this process of processing and utilizing, because of its isotropic feature and provide an outstanding surface finish and prolonged tool life. |

|

|

|

|

| cvd wire drawing die |

cvd wire drawing die |

|

|

|

Applications

CVD diamond die blanks works extremely well in cold and hot wire drawing of varied types of metal, particularly tungsten, high hardness steel, forceps, copper and aluminum wires. |

| CVD diamond wire drawing die common sizes in mm (R/H) |

|

| 1206 |

1208 |

1210 |

1515 |

3820 |

| 1506 |

1508 |

1510 |

2015 |

4020 |

| |

1808 |

2510 |

2515 |

5225 |

| |

2008 |

3010 |

3015 |

|

| |

2508 |

|

3215 |

|

|

| |

Poly crystalline Diamond (PCD) wire drawing die

Polycrystalline diamond wire drawing dies as a base material could be effectively applied in virtually any wire drawing operations, from rod size to advanced and fine size wires. |

|

|

|

|

| pcd wire drawing die |

pcd wire drawing die |

pcd wire drawing die |

|

|

|

Applications

These wire drawing dies which can be used for a wide variety of drawing applications as it provides a high potential to deal with wear, cracking and a fantastic wire surface finish. The dies could be applied on wire types of aluminum, copper, tungsten, molybdenum, stainless steel, coated steel, special and powerful alloy wire, precious metal, non-ferrous and ferrous wire drawing applications. |

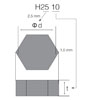

| Specification |

Size (mm) |

|

| Inner diameter(d) |

Thickness(T) |

| D6-R2510 |

2.5 |

1.0 |

| D12-R3215 |

3.2 |

1.5 |

| D15-R5225 |

5.2 |

2.5 |

| D18-R5235 |

5.2 |

3.5 |

| D21-R8040 |

8.0 |

4.0 |

| D24-R9853 |

9.8 |

5.3 |

|

| |

| Specification |

Size (mm) |

|

| Inner diameter(d) |

Thickness(T) |

| D6-H2510 |

2.5 |

1.0 |

| D12-H3215 |

3.2 |

1.5 |

| D15-H5225 |

5.2 |

2.5 |

| D18-H5235 |

5.2 |

3.5 |

| D21-H8040 |

8.0 |

4.0 |

| D24-H9853 |

9.8 |

5.3 |

|

| |

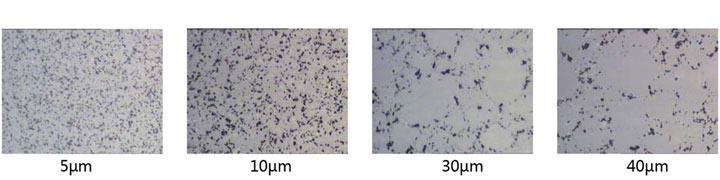

Imported PCD wire drawing die

Imported diamond microstructure wire drawing dies is in compact, stream-lined and homogeneous distribution, and this diamond wire drawing die has highlights of excellent abrasive resistance, prolonged service life, great smooth finish. This is suitable for wire drawing of brass, steel and all kinds of non ferrous metal wire and alloy wire. |

|

|

|

|

| imported pcd wire drawing die |

imported pcd wire drawing die |

|

|

|

Applications

This can be applied on soft wire materials of gold, platinum, silver, brass, phosphor bronze and aluminum and on hard wire metal types, iron, stainless steel, nickel, chrome, molybdenum, tungsten, copper clad steel and so forth. |

| Specification |

Size (mm) |

|

| Inner diameter(d) |

Thickness(T) |

| D6-H2510 |

2.5 |

1.0 |

| D12-H3215 |

3.2 |

1.5 |

| D15-H5225 |

5.2 |

2.5 |

| D18-H5235 |

5.2 |

3.5 |

|

| |

PCD with carbide ring cold press type wire drawing die

These have PCD core integrally glued to a tungsten carbide support ring and all die blanks include a metal catalyst in PCD composition. Diamond core might be pierced utilizing either EDM, ultrasonic, laser or needle techniques and temperature shouldn't go beyond 700°C in die mounting procedures. Profiling of the die geometry is generally carried out using molded needles with EDM or ultrasonic devices with diamond abrasives and is electrically conductive. |

|

|

|

|

| cold press pcd wire drawing die with carbide ring |

cold press pcd wire drawing die with carbide ring |

|

|

|

Applications

These are used in applications exactly where remarkable top quality and crucial surface quality and finish, is a must i.e., non-ferrous and ferrous intermediate and fine wires, Intermediate and rod breakdown drawing of copper and aluminum materials. |

| Specification |

Size (mm) |

Eccentricity tolerance (mm) |

|

| Outer diameter(D) |

Inner diameter(d) |

Thickness(T) |

| D15-R4023 |

9.50 |

4.50 |

2.30 |

≦0.2 |

| D18-R4029 |

9.50 |

4.50 |

2.90 |

≦0.2 |

| D21-R7040 |

14.00 |

7.60 |

4.00 |

≦0.25 |

| D24-R7053 |

14.00 |

7.60 |

5.30 |

≦0.25 |

| D27-R12080 |

28.00 |

13.00 |

8.00 |

≦0.25 |

| D30-R150120 |

30.00 |

15.00 |

11.50 |

≦0.25 |

|

| |

There is a fast growing necessity of wire drawing dies and to fulfill this need many countless miles of wire are pulled by metal working firms every year. For this purpose wire drawing, even though the same in process for several years, is definitely a price sensitive and reasonably competitive market. Thus, the companies that produce wire drawing dies and the process equipments around wire drawing are extremely in track to any efficiency or productivity benefit they can get. |

|

We export impregnated and surface set diamond core bits, diamond casing and casing shoe bits, reaming shells, core barrels, drilling rods, overshots to world wide countries, such as USA united states, Germany, UK united kingdom, Italy, France, Turkey, Russia, Ukraine, Canada, South Africa, Philippines, Cambodia, Thailand, Malaysia, Australia, New Zealand, South Korea, Japan, Israel, Cyprus, Finland, Sweden, Norway, Danmark, Poland, Czech, Hungary, Switzerland, Ireland, Holand, Greece, Croatia, Spain, Portugal, Egypt, India, Singapore, Indonesia, Saudi Arabia, United Arab Emirates, Mexico, Brazil, Colombia, Peru, Chile, Argentina etc. |