|

| Home >> technical info >> Drilling parameters about influence factors of rotary speed, drilling pressure, flushing water |

The Selection of the Drilling Parameters: |

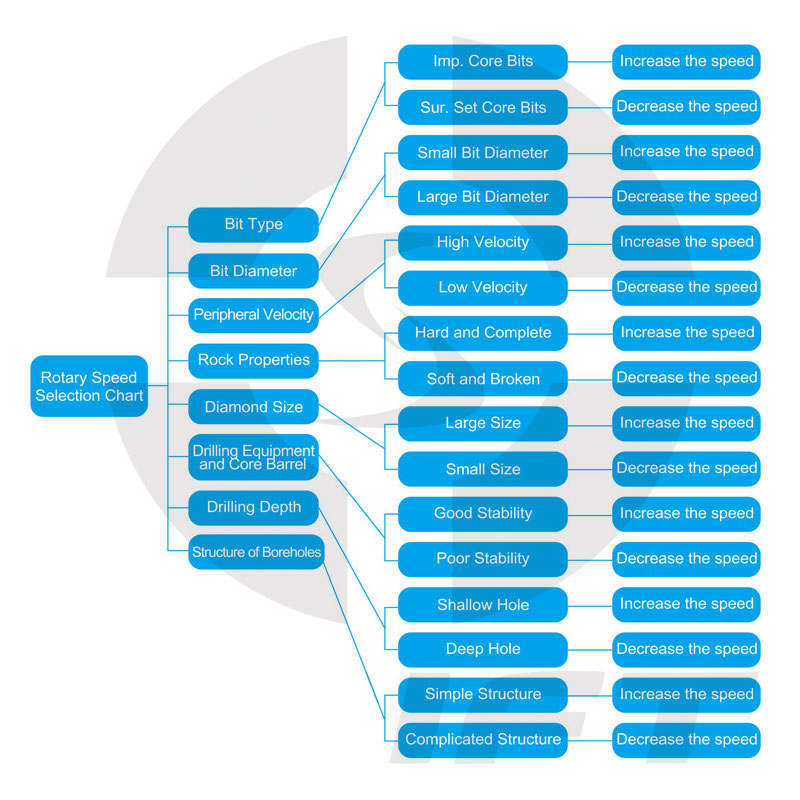

1). Influence Factors of Rotary Speed |

When deciding the specific peripheral velocity of bits, in addition to bit type and bit diameter, other factors such as rock

properties, diamond size, drilling equipment and core barrel, drilling depth and the structure of drilling holes, should be

considered also. |

|

① Bit Type: The natural diamond grains on surface set core bit are large and self-sharpening easily, in order to protect the exposed diamond grains, the rotary speed of surface set core bit should be lower than the impregnated core bit. |

② Bit Diameter: In order to reach a proper linear velocity, the rotary speed of the small diameter bit should be higher than the big diameter bit. |

③ Peripheral Velocity: From the formula of rotating speed, we can find the liner velocity is proportionate to the rotating speed. It means the higher speed of the liner velocity, rotating speed is accordingly higher. |

④ Rock Properties: High rotary speed is suitable for medium hard, complete rock formations; in broken, fractured, mixed formations, with high vibration during drilling, drillers should slow down the rotary speed according to the broken level of the rock; in the soft formations with high drilling efficiency, in order to keep cooling and carry out the cuttings, the penetration speed needs to be limited, as well as the rotary speed. |

⑤ Diamond Size: The larger the diamond size, the quicker the self-sharpening. To avoid the bit face chipped or cracked, the rotary speed of the bits with big diamonds should lower than the bits with small diamonds. |

⑥ Drilling Equipment and Core Barrel: When the drilling machine is with poor stability and the drill rods have a low intensity, correspondingly, the rotary speed should be slowed down. If the lubricants or other similarities for decreasing the vibration are adopted, the rotary speed could be raised. |

⑦ Drilling Depth: when the depth of the drilling hole becomes deep, the weight of the core barrels will be larger; the pressure situation is more complex; it takes larger power while rotating the core barrels. Hence, in the deep hole, because of the limit of the power and intensity of the core barrels, the rotary speed should be decreased; in shallow hole, conversely. |

⑧ Structure of Drilling Holes: High rotary speed can be used in the condition that the borehole structure is simple and the clearance between the drill rods and borehole wall is small. On the contrary, the drilling hole with a complex situation, lots of changeable diameters, big space between the drill rods and borehole wall, it causes poor stability and can’t use the high rotary speed. |

|

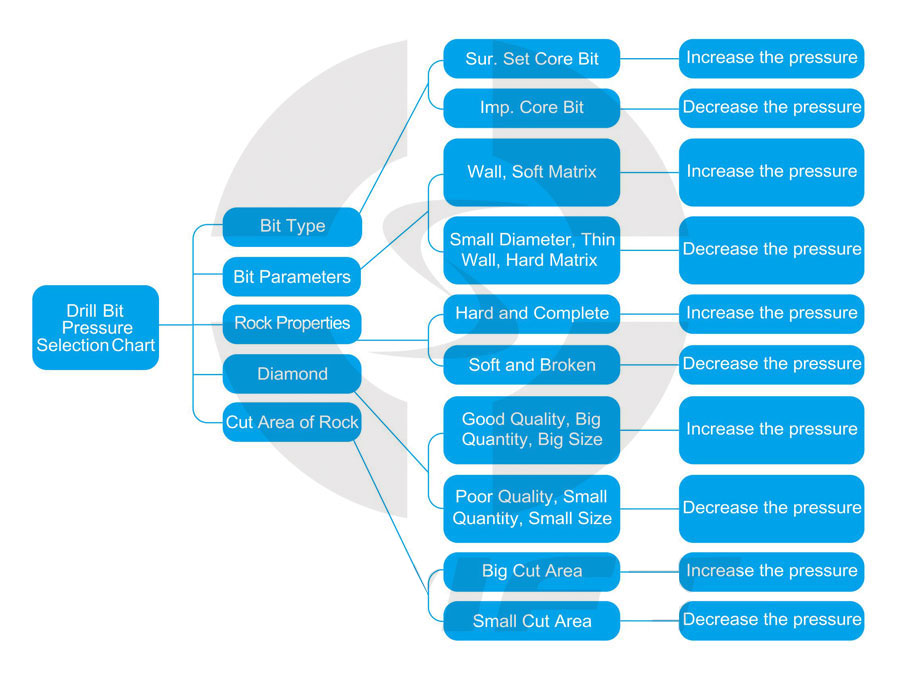

2). Influence Factors of Drilling Pressure |

|

① Rock Properties: The smaller drilling pressure should be used in soft to medium soft formations. The Drilling pressure should be increased properly in complete, medium hard and hard formations. In broken, cracked and mixed formation, the drilling pressure should be reduced properly according to cracking level of the formations. |

② Bit Type: Greater drilling pressure can be adopted for the bits which have big diameter, thick wall and soft matrix. The bits with small diameter, thin wall and hard matrix, the drilling pressure should be smaller. The drilling pressure for surface set core bit should be higher than impregnated core bit, in order to make the diamonds on surface set core bit to drill into the rock and cause its brokenness. |

③ Diamond Quality, Diamond Quantity, Diamond Size: Drilling pressure should be bigger when diamond quality is good, quantity is big and the grain size is large; on the contrary, smaller drilling pressure should be adopted when the diamonds are with poor quality, small quantity and small grain size. The total drilling pressure on the bits which are with large-sized but fewer diamonds should be lower than the one on the bits which are with small-sized but more diamonds. |

④ Cut Area of the Rock: The cut area of the rock depends on the bit diameter, wall thickness and waterway quantities. The larger the coring area, the higher the drilling pressure. Conversely, the drilling pressure should be lower. |

|

3). Influence Factors of Flushing Water |

① Rock Formation Properties and the Level of the Completeness: while drilling into hard and fine-grained formations with low rotary speed and few cuttings of small grain size, the flushing water could be less; in soft, medium hard and coarse-grained formations with high rotary speed, the flushing water should be increased to discharge the debris effectively. |

② Bit Type: High rotary speed is usually used on impregnated core bits. Because of the fine diamond grains on impregnated core bits, more flushing water should be used to cool the diamond grains and the matrix of impregnated core bits, so as to avoid the diamonds damaged from oxidation and graphitization, and protect the bit matrix from being worn too fast by the debris. The self-sharpening ability of surface set core bits is better than that of impregnated core bits. Also, surface set core bits have advantages on debris removal and cooling, so its flushing water can be a little less than that of Impregnated core bit. |

③ the performance of the bit matrix, diamond sizes, bit waterways, rotary speed, drilling pressure also affect the flushing water. Those all should be taken into consideration. |

|

|

We export impregnated and surface set diamond core bits, diamond casing and casing shoe bits, reaming shells, core barrels, drilling rods, overshots to world wide countries, such as USA united states, Germany, UK united kingdom, Italy, France, Turkey, Russia, Ukraine, Canada, South Africa, Philippines, Cambodia, Thailand, Malaysia, Australia, New Zealand, South Korea, Japan, Israel, Cyprus, Finland, Sweden, Norway, Danmark, Poland, Czech, Hungary, Switzerland, Ireland, Holand, Greece, Croatia, Spain, Portugal, Egypt, India, Singapore, Indonesia, Saudi Arabia, United Arab Emirates, Mexico, Brazil, Colombia, Peru, Chile, Argentina etc. |